Cold Formed Steel Construction – University Lofts

University Lofts was a project located in downtown Binghamton, NY. Originally, a department store was on the site, and the facade was left in place. There was a serious fire inside of the building, so the owner tore out the interior. To rebuild it, the owner decided to use cold formed steel construction. The contractor used custom rolled sections using the Howick Machine. The steel supplier was Vanguard Light Gauge Steel Buildings in Winchester, VA. Vanguard contracted with us to provide the structural engineering services.

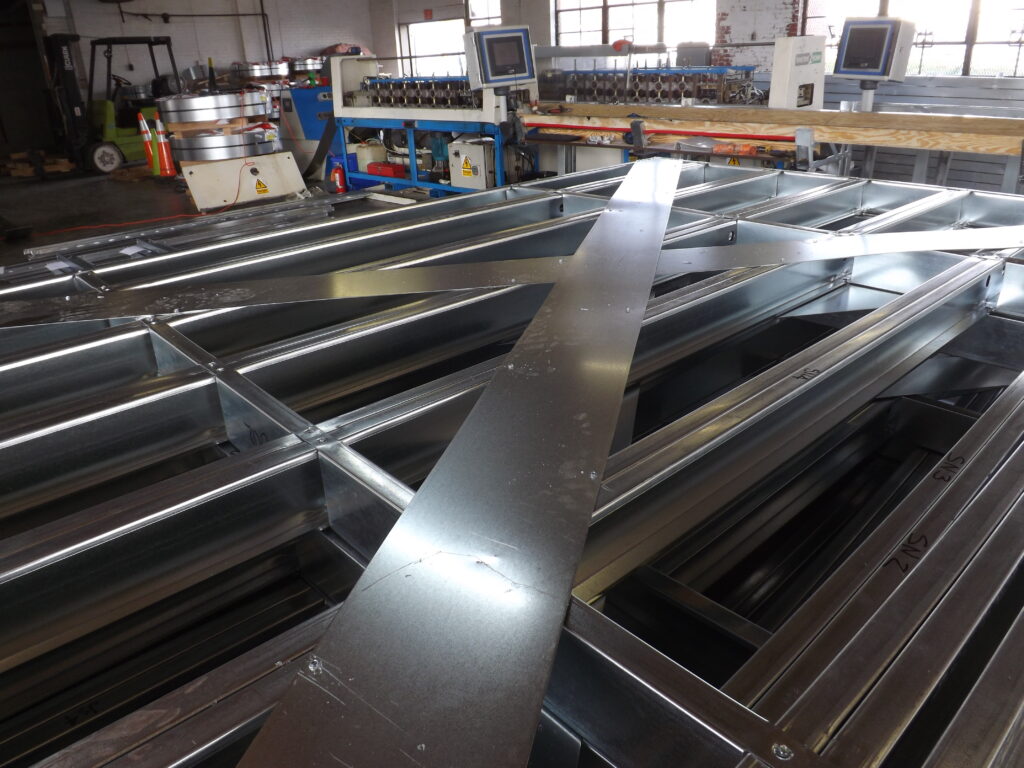

Fabrication

With this system, the fabricator purchases rolls of light gauge steel. The fabricator inputs building wall and floor system information into the machinery program. The machinery program then controls a rolling machine to output the sections. There is very little wastage, and there is a lot of control over the fabrication. The contractor does not have to cut light gauge steel on site. Also the fabricator does most of the attachments in the shop.

The fabricator assembled the walls as panels and assembled the floor trusses in Winchester. They then hauled them up to Binghamton, where the contractor erected them. In addition to rebuilding the interior of one building, we structurally designed a 3 story addition to the building behind the one that the fire gutted. We designed the addition as hot-rolled structural steel framing with cold formed steel and composite concrete metal decking for the floors, and cold formed steel walls.

With the fabricator assembling most of the sections in a shop environment, the contractor can compress their schedule significantly. The contractor doesn’t get affected so much by weather, because much of the work is done by the fabricator indoors.

Critical Items

With cold formed steel construction of this type, there are some things that are critical:

- Drawing accuracy is critical. It is important to have a good survey of the site before proceeding. The contractor must have the foundations laid out accurately. Prior to fabrication, it is important to recheck the layout of the foundations. Any errors will cause serious problems with erection.

- Quality control is important. The fabricator must verify that they have done the connections at the joints correctly. While highly skilled labor isn’t needed, it is important the the person assembling the sections can handle driving the screws and understands how they are to be placed (not bunched together).

- Truss design can be an issue. The engineer should design the trusses first, not the person working with the software for the machine. It saves a lot of effort if the fabricator standardizes the design of the trusse, and quality control is better too.

- Prior to fabrication, the engineer must check the shop drawings. The fabricator should not assemble sections until the engineer has had a chance to review and approve the shop drawings.