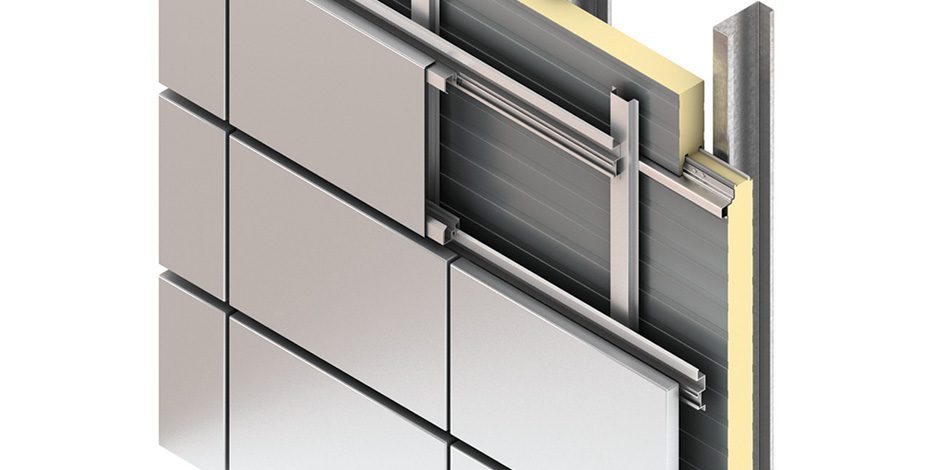

ACM, short for aluminum composite materials, is a material commonly used in building cladding. ACM panels are made of thin layers of aluminum sheets surrounding a plastic core such as polyethylene, which is typically made to be fire resistant in high rise buildings. The plastic offsetting the two aluminum faces allows the panel to be stronger than a thinner panel with the same amount of aluminum without the cost increase of using thicker aluminum sheets.

At Runkle Consulting, our structural engineers have extensive experience in evaluating ACM panel systems. We specialize in reviewing shop drawings and providing precise structural calculations for panels exposed to both wind and potential seismic loads. Our team has contributed to the design and analysis of buildings across the Eastern United States, including projects in Florida, Georgia, Texas, New York, North Carolina, and more.

ACM is frequently used in commercial and educational facilities, and our engineering team has worked on a wide range of structures, including schools, university buildings, office complexes, and hotels.

Analysis of ACM panels must consider not only the behavior of the panels themselves but also of their connections. The primary loads on cladding panels come from wind, which can cause deflections and stresses in the panel’s face. The panels transfer these loads to their connections, and the pulling forces on screws from negative wind pressure is often the controlling element in a cladding system —a challenge our structural engineering experts are highly skilled at resolving.

Send Us a Message

Reach out to us to discuss your ACM Panel Cladding Project